Plasti-Fab is a recognized leader in the North American Expanded Polystyrene

(EPS) industry, and provides specialized technical expertise to guide new and existing customers toward the best products for their applications.

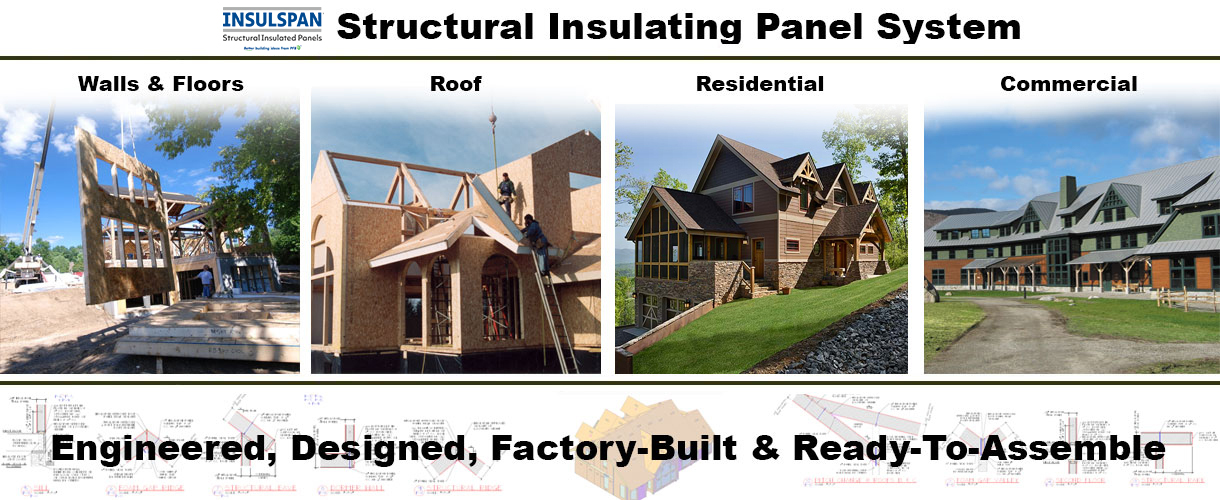

The Insulspan SIP (structural insulated panel) System consists of solid, one-piece pre-cut SIPs that are ready to install as energy efficient wall, floor, and roof components in residential and commercial building applications.

Plasti-Fab’s mission is to provide its customers with expanded polystyrene (EPS) Product Solutions for constructing energy efficient buildings, flotation for marine construction, lightweight fill and compressible fill for Geotechnical construction projects, and component solutions for Original Equipment Manufacturers.

Plasti-Fab products provide excellent insulating qualities in a cost effective way that reduces energy consumption in heating and cooling of buildings. Its products are an integral component for many LEED® certified buildings and Net Zero Energy Homes. Plasti-Fab operates nine manufacturing facilities that produce EPS insulation, Insulating Concrete Forms (ICFs) and Structural Insulating Panels (SIPs) for the Canadian and United States construction markets. Strategically located across North America, the facilities reduce distribution costs to Building Supply Stores, Construction Specialty Distributors and Contractors customers.

Plasti-Fab creates lasting communities by innovating Expanded Polystyrene (EPS) products for construction and civil infrastructure applications. Our customers are homeowners seeking energy efficiency, contractors who want a competitive edge, and building professionals who need comprehensive solutions.

Our core values drive everything we do. We prioritize cost-effectiveness by offering EPS solutions that outshine other insulation products, delivering the best price per inch of R-Value with no diminishing returns over time. Our commitment to health and sustainability is evident in our GREENGUARD certified EPS products, which boast superior material properties and a lifetime Global Warming Potential 34 times lower than XPS. Through vertical integration, from resin manufacturing to product development, we ensure quality control and innovation every step of the way. Furthermore, we foster stronger communities by creating local jobs, supporting regional manufacturing, and actively engaging in building and standards associations while promoting employee safety.

PlastiSpan®, DuroSpan®, EnerGreen® GeoSpec®, GeoVoid® and EnerSpan™ and RadonGuard™ are all registered trademarks of Plasti-Fab Ltd.

The Advantage ICF System® by Plasti-Fab is a mainstream building product. Its popularity continues to grow as architects, specifiers, building contractors, and the public at large become familiar with the benefits of using Insulating Concrete Forming (ICF) systems in residential and commercial construction projects.

Advantage ICF is a one-piece, stay-in-place, insulating concrete form made of expanded polystyrene (EPS) insulation. A series of strong plastic web connectors are permanently molded into two EPS panels to create a building block. The integral plastic webs act as the studs in a wall assembly, and are spaced at either 6 or 8 inches on center.

Advantage ICFs have a patented interlocking system along the top and bottom edges, which allows the blocks to securely connect together, much like kids’ Lego™ blocks. Reinforcing steel is placed on the plastic web connectors inside the block cavity which is then filled with concrete. After the concrete pour, the insulating EPS remains in place on both sides of the structure, providing a highly energy-efficient building envelope.

Insulspan, with more than 30 years’ experience in the building industry, is a leading brand of SIPs in North America.

Take a piece of our environmentally friendly EPS, laminate it between two layers of structural oriented strand board, and you have one of the world’s finest insulating building components: an Insulspan® Structural Insulating Panel (SIP).

Insulspan Structural Insulating Panel Systems (SIPs) are used to create a building’s structural wall frame and replace trusses on roof systems to form an extremely energy-efficient structural “envelope.” This type of structural building envelope is so energy efficient that BASF chose Insulspan® SIPs for inclusion in its pioneering “Home, Sweet Hybrid Home,” the Net Zero Energy House built in a residential development in Paterson, New Jersey. This home recently earned a “Platinum” rating from the U.S. Green Building Council’s LEED®-H Rating System, one of only two houses in the whole of North America to achieve that rating.

In addition, the LEED® for Homes Rating System now grants certification credits for the use of SIPs in home construction. The LEED®-H Rating System specifically recognizes the “Material and Resource Efficiency” of SIPS.

Insulspan SIPS are the only SIPS in North America manufactured under ISO 9000 certification and the only SIPS with both U.S. and Canadian code listings.